We would like to make an order of "285nm SiO2 on Si" substrates for the growth of 2D materials. In fact, my colleague already contacted you and we learnt that 2" P(100) 1-10 ohm-cm SSP 500um with 285nm of oxide.

2D Material Substrates

Thermal Oxide Coated Silicon for Growing 2D Materials

An assistant university professor requested a quote for the following.

Reference #188309 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

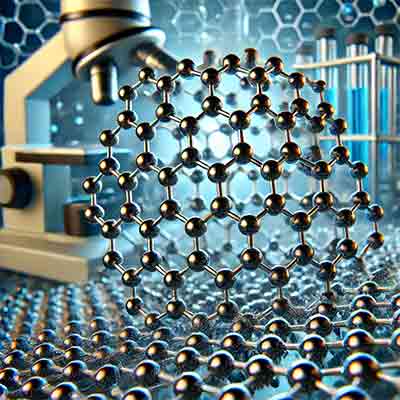

SiO2/Si Substrates Exfoliation of 2D Material

A posdoc requested a quote for the following.

285nm oxide thickness desired, only 10 wafers needed. We do low temperature optical measurements and I"ve noticed that other SiO2/Si substrates can give fluorescence peaks that are due to defects. Can you quantify defect density in your wafers?

Reference #209209 for specs and pricing.

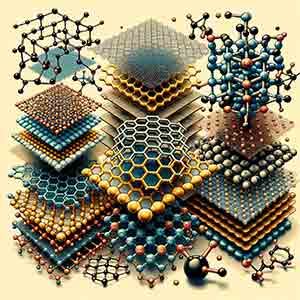

What Are 2D Materials?

2D materials are crystalline solids consisting of a single layer of atoms, meaning they have a thickness of just  one or a few atomic layers. They exhibit unique electrical, optical, mechanical, and thermal properties due to quantum confinement effects. These materials have applications in nanoelectronics, photonics, sensors, energy storage, and quantum computing.

one or a few atomic layers. They exhibit unique electrical, optical, mechanical, and thermal properties due to quantum confinement effects. These materials have applications in nanoelectronics, photonics, sensors, energy storage, and quantum computing.

Examples of 2D Materials:

- Graphene (Single layer of carbon atoms)

- Hexagonal Boron Nitride (hBN) (Electrical insulator with high thermal stability)

- Transition Metal Dichalcogenides (TMDs) (e.g., MoS₂, WS₂, MoSe₂, WSe₂ - Semiconductors)

- Black Phosphorus (BP) (Tunable bandgap and high carrier mobility)

- MXenes (Conductive ceramics with high electrochemical activity)

Substrates Used for 2D Materials

Since 2D materials are atomically thin, their properties are highly influenced by the choice of substrate. Common substrates include:

-

Silicon with SiO₂ Layer

- Most commonly used due to ease of fabrication and optical contrast for microscopy.

- The oxide layer (usually 285 nm SiO₂) enhances visibility under an optical microscope.

- Can cause charge traps affecting electronic performance.

-

Sapphire (Al₂O₃)

- Used for high-quality growth of TMDs and graphene.

- Chemically inert and has a high thermal stability.

- Reduces lattice mismatch effects in epitaxial growth.

- Used for high-quality growth of TMDs and graphene.

-

Mica

- Ultra-smooth surface ideal for van der Waals interactions.

- Commonly used for exfoliated 2D material studies.

- Minimizes charge inhomogeneity.

-

Hexagonal Boron Nitride (hBN)

- Often used as an encapsulating layer to protect 2D materials from contamination.

- Reduces surface roughness and charge fluctuations.

- Enhances carrier mobility when used as a substrate for graphene.

-

Quartz (SiO₂)

- Transparent, used in optical applications.

- Can support direct growth of 2D materials.

-

Metal Substrates (Cu, Ni, Pt, Au, Ag, Mo, W)

- Common for CVD growth of graphene and TMDs.

- Metals like Cu enable large-scale graphene synthesis.

-

Polymers (PMMA, PDMS, Polyimide)

- Used as transfer substrates for exfoliated or CVD-grown materials.

- Flexible and can enable strain engineering.

-

- Used for optoelectronic and display applications.

- Offers transparency and chemical stability.