I am looking to source a new supplier for 4” 128 Y-cut LiNbO3 Black 500um (or thicker) SAW wafers for PhD research work front side polish or double side. It would be small orders at a time 1 to 10 as needed. Could you please provide a quote?

What Are LiNbO3 Substrate's Applications?

LiNbO3 Supplier

A PhD Candidate of the DTC in Cell & Proteomic Technologies needed a new LiNbO3 supplier.

UniversityWafer, Inc. Quoted:

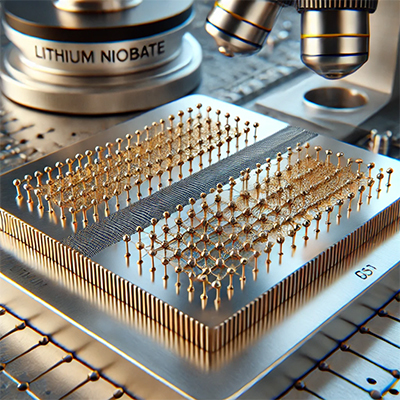

Blacked LiNbO3 Wafer

4", Y-128 Degree, SSP, SAW Grade, 500um thick

Reference #153507 for specs and pricing.

SAW Delay Lines

An Associate Research Scientistn requested the following quote.

Do you have 4-inch, 0.5 mm thickness LiNbO3 Wafers 127.680 Y-X rotated cut,xpropagating available? I need these wafers for SAW delay lines so please make sure that they have good quality and piezoelectric coefficients.

Reference #320299 for specs and quantity.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

How Are LiNbO3 Substrates Used in SAW Delay Lines?

Breaking down lithium niobate

Lithium niobate, a piezoelectric crystal, is employed in SAW delay lines due to its significant electromechanical  coupling coefficient, ensuring robust acoustic signals with minimal insertion loss and stable physical characteristics.

coupling coefficient, ensuring robust acoustic signals with minimal insertion loss and stable physical characteristics.

Emphasizing key substrate advantages

Lithium niobate's high piezoelectric coupling and temperature stability, paired with orientation and minimization of conduction losses via doping, underscore its critical role in SAW delay lines.

Understanding integration

Certainly, let me see. Lithium niobate substrates integrate IDTs for SAW generation and reception, focusing on spatial patterns, velocity control, and crystal orientation for optimized delay performance.

Lithium niobate (LiNbO₃) is one of the most widely used piezoelectric crystals for surface acoustic wave (SAW) devices—including delay lines—because of its excellent electromechanical coupling, relatively high SAW velocity, and good overall stability. Below is an overview of how LiNbO₃ substrates are typically employed in SAW delay lines:

1. Piezoelectric Substrate

-

Piezoelectric Property

LiNbO₃ is strongly piezoelectric, meaning it can efficiently convert electrical signals into mechanical (acoustic) waves and back into electrical signals. This property is key in SAW devices, where interdigitated transducers (IDTs) launch and receive acoustic waves on the crystal surface. -

High Electromechanical Coupling

Among commonly used SAW substrates (e.g., LiTaO₃, quartz, etc.), LiNbO₃ has a relatively high electromechanical coupling coefficient. This leads to stronger SAWs with lower insertion loss and allows for more compact device designs.

2. Choice of Crystal Orientation

-

Cut and Orientation

SAW devices on LiNbO₃ are often fabricated on specific crystal cuts—like the 128°-rotated Y-cut—to optimize performance parameters such as coupling coefficient, temperature stability, and insertion loss. Different orientations can tailor the velocity of the acoustic wave and minimize unwanted spurious modes or temperature drift. -

Surface Acoustic Wave Velocity

The velocity of the surface wave depends strongly on the crystal orientation. In SAW delay lines, a higher propagation velocity can be advantageous to achieve shorter transit times over a given distance, or conversely, to allow a longer physical path for a given delay without a large chip area.

3. Interdigitated Transducers (IDTs) Fabrication

-

Substrate Preparation

- The LiNbO₃ wafer is polished to an appropriate thickness and surface finish.

- Orientation and cut are chosen based on the target operating frequency, bandwidth, and temperature performance.

-

IDT Patterning

- A thin metal film (commonly aluminum or sometimes copper or gold alloys) is deposited on the surface.

- Photolithographic techniques define the interdigitated transducer patterns.

- The electrode spacing determines the SAW wavelength and thus the operating frequency.

-

Electrode Metallization

- After patterning, the wafer is usually diced into individual die.

- Each SAW delay line die has one or more pairs of IDTs: input transducers to launch the wave and output transducers to detect (receive) the wave.

4. Operation in a Delay Line

-

Signal Input and SAW Generation

- An RF signal is applied to the input IDT, which converts the electrical signal into a mechanical surface wave via the piezoelectric effect.

-

Propagation and Delay

- The acoustic wave travels along the surface of the LiNbO₃ substrate.

- The transit time from the input IDT to the output IDT corresponds to the delay introduced into the signal path.

-

Signal Detection

- When the SAW reaches the output IDT, it induces a corresponding electrical signal in the transducer electrodes.

- This output is a delayed version of the input signal, with the delay determined primarily by the distance between transducers and the SAW velocity.

5. Key Advantages of LiNbO₃ in Delay Lines

-

Low Insertion Loss

Thanks to strong electromechanical coupling, the conversion losses from electrical to acoustic energy (and back) are relatively low. -

Compact Device Design

High coupling efficiency and higher SAW velocity can allow the device to be physically smaller for a given delay time compared to some other substrates. -

Frequency Range

LiNbO₃-based SAW devices can operate over a wide frequency range, from tens of MHz to several GHz, depending on the precision of the IDT patterning. -

Mass Production Suitability

LiNbO₃ wafers are commonly available in standard diameters (e.g., 3”, 4”, 6”), making it feasible for batch manufacturing using standard semiconductor processes.

Summary

In a SAW delay line on a LiNbO₃ substrate, the core idea is straightforward: interdigitated electrodes convert electrical signals to acoustic waves that travel across the crystal surface, introducing a precise time delay. LiNbO₃’s strong piezoelectric effect, high electromechanical coupling coefficient, and favorable acoustic properties make it a go-to material for SAW delay lines (and SAW filters) in applications requiring compact size, robust performance, and predictable delay characteristics.