Substrates for Nanomanufacturing

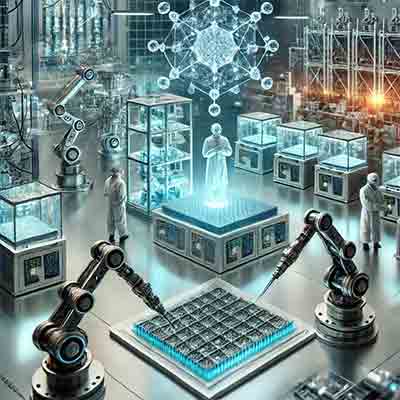

High-Rate Nanomanufacturing (HRN)

High-Rate Nanomanufacturing (HRN) refers to the large-scale, high-throughput production of nanoscale materials, structures, and devices with precision, repeatability, and efficiency. The goal of HRN is to transition nanotechnology from small-scale, research-focused fabrication to industrial-level mass production, making nano-enabled products commercially viable.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What Substrates Often Used For Nanomanufacturing?

Nanomanufacturing relies on substrates that provide high precision, stability, and compatibility with nanoscale fabrication processes. The choice of substrate depends on the application, required material properties, and processing conditions. Here are some commonly used substrates:

1. Silicon (Si)

- Single-crystal Silicon: Most widely used due to its well-understood properties and compatibility with

semiconductor processes.

semiconductor processes. - Silicon-on-Insulator (SOI): Ideal for MEMS, sensors, and advanced CMOS devices due to reduced parasitic capacitance and better device isolation.

- Porous Silicon: Used in RF devices, biosensors, and photonics.

2. Glass & Quartz

- Fused Quartz (SiO₂): High optical transparency and thermal stability; commonly used in photonics and optical MEMS.

- Borosilicate Glass: Low thermal expansion, used in microfluidics and biomedical applications.

- Sapphire (Al₂O₃): Excellent mechanical strength, high-temperature stability, and electrical insulation, widely used for LEDs and RF devices.

3. III-V Semiconductor Substrates

- Gallium Arsenide (GaAs): Used in high-frequency electronics, optoelectronics, and laser diodes.

- Gallium Nitride (GaN): Suitable for high-power and high-frequency devices like LEDs and RF amplifiers.

- Indium Phosphide (InP): Essential for high-speed optoelectronics and photonic devices.

4. Metal & Metal-coated Substrates

- Gold (Au), Platinum (Pt), Titanium (Ti): Often used for biosensors and conductive surfaces.

- ITO (Indium Tin Oxide) Glass: Transparent and conductive, essential for touchscreens, photovoltaics, and flexible electronics.

5. Polymer & Flexible Substrates

- PDMS (Polydimethylsiloxane): Used for microfluidics, soft lithography, and biomedical devices.

- PI (Polyimide) & PET (Polyethylene Terephthalate): Common in flexible electronics and wearable sensors.

6. Carbon-based Substrates

- Graphene: Highly conductive and used in advanced nanoelectronics, sensors, and energy storage.

- Diamond: Used in high-power electronic devices and quantum computing due to its extreme hardness and thermal conductivity.

Would you like recommendations based on a specific nanomanufacturing application?