We would like a few samples of GaAs that would be suitable for educational laboratory testing. The application is for photovoltaic cells. It would be also useful to have similar sets of InP.

How To Make Photovoltaic Cells?

III-V Substrates for Photovoltaic Cells

A postdoc requested a quote a photovoltaic cell application.

Reference #110112 for specs and pricing.

Thin Silicon Wafers for Photovoltaic Cells

A solar panel engineer requested a quote for the following.

Could you let us know if you have really thin silicon wafers of the type used for photovoltaic cells? The thickness would be in the range of 100um to160um; diameter of 5" would be fine. We would need just a couple. We'd need to know price.

Reference #145479 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Solar Firms Requests Help with Their Photovoltaic Wafer

Our firm provides heating

systems with solar panels.

Recently, we have been developing

a new line of products: solar

concentrators for electric

generation (with photovoltaic

wafers and Fresnel lenses)

For the solar concentrators to be

competitive, we need to get

photovoltaic wafers of high

quality and durability and that

allow us to reach a high

efficiency level of conversion

from solar energy to electricity.

It is important to note that our Project includes de development of two types of concentrators; hence, we will need two different kind of photovoltaic wafers

- Concentrator 1: Solar concentrator with cooling system with some liquid (water, glycol, etc.), aimed to improve the performance of photovoltaic wafers. This product would be able to heat water as a by- product.

- Concentrator 2: Solar

concentrator to be used in areas

with restricted water supply. No

cooling system should be required

or it should operate with an

alternative technology like a

heat dissipater.

We are very interested in your technical assistance and expertise to advise us on the options available in photovoltaic wafers to be used in the concentrators, in order to guide us in the purchase of the right< components.

Please be so kind to send us information on the characteristics and prices of the photovoltaic cells you provide, taking into account our technical needs,

Reference #123401 for specs and pricing.

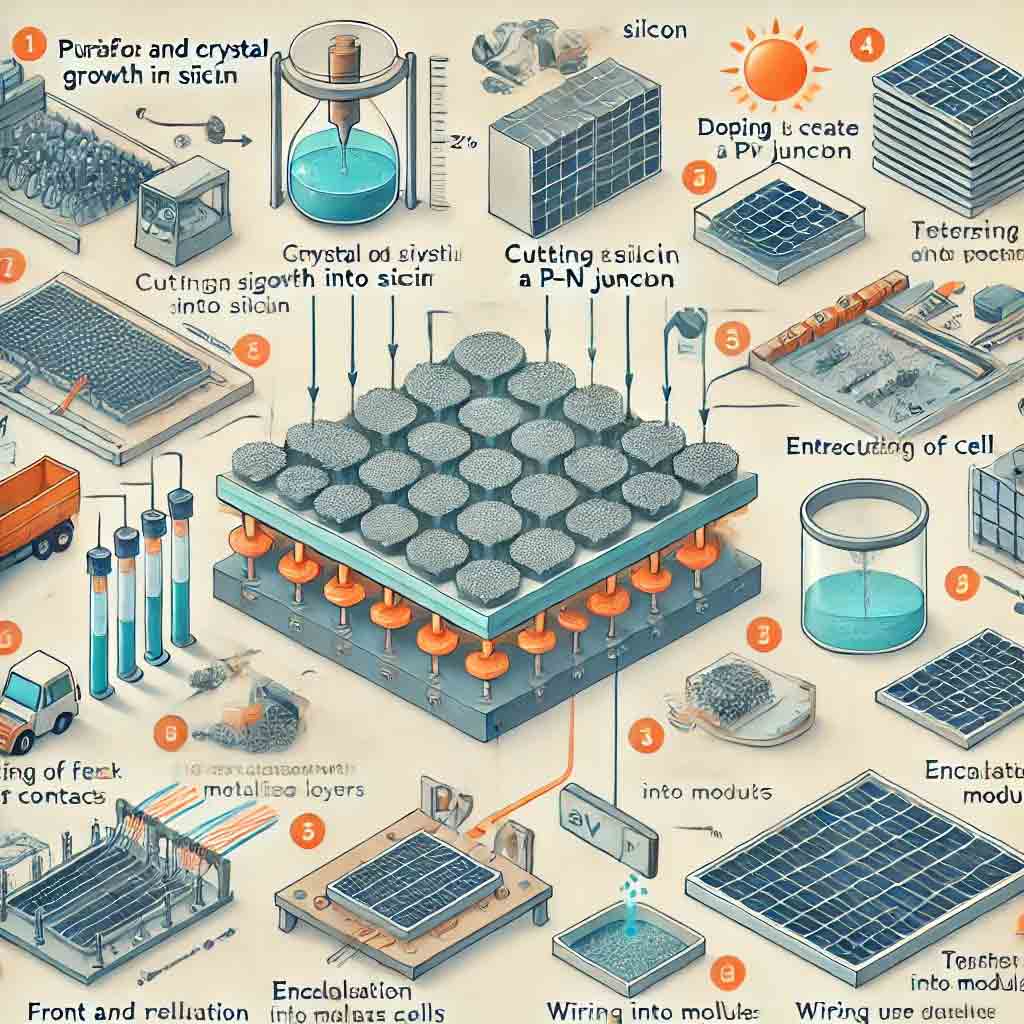

Fabricating Photovoltaic Cells

Making photovoltaic (PV) cells involves multiple steps, from the selection of materials to the assembly of the final device. Here’s a breakdown of the process:

1. Material Selection

- Semiconductor Material: Silicon is the most common material due to its abundance, efficiency, and stability. Other materials include:Thin-film materials: Cadmium telluride (CdTe), copper indium gallium selenide (CIGS).Emerging materials: Perovskites, organic PV materials.

- Substrate: Often glass, metal, or plastic for thin films, or silicon wafers for traditional cells.

2. Wafer Production (for Silicon-based PV Cells)

- Purification: Silicon is extracted from quartzite and purified to electronic grade.

- Crystal Growth:Monocrystalline silicon: Made using the Czochralski method to create a single-crystal ingot.Polycrystalline silicon: Made by casting molten silicon into molds.

- Wafer Cutting: The silicon ingots are sliced into thin wafers (~150-200 µm thick).

3. Doping

- Doping silicon with phosphorus (n-type) and boron (p-type) creates a p-n junction, essential for generating electricity in response to sunlight.

4. Texturing

- The wafer surface is textured (etched) to reduce reflection and increase the absorption of sunlight.

5. Anti-reflective Coating

- A thin anti-reflective layer is applied to the surface to maximize light absorption.

6. Metallization

- Front Contacts: Fine grid lines (silver paste) are printed or deposited on the front surface to collect and transport electrons.

- Back Contacts: A conductive layer (often aluminum) is added to the back of the cell to complete the circuit.

7. Encapsulation

- The cells are encapsulated with transparent EVA (ethylene vinyl acetate) to protect them from moisture, dust, and mechanical stress.

8. Assembly into Modules

- Cells are wired together to form a module.

- Encapsulated cells are sandwiched between:Glass on the top: For durability and transparency.Backsheet on the bottom: For insulation and weather resistance.

- The module is framed for structural support and fitted with a junction box for electrical connections.

9. Testing

- Each module is tested under standard test conditions (STC) to ensure it meets power output and quality standards.

10. Installation

- Modules are installed in arrays to capture sunlight effectively. They are connected to inverters to convert the generated DC electricity to AC for use in homes or the grid.

Advanced Manufacturing Techniques

- Thin-film technologies: Use deposition methods (e.g., sputtering, vapor deposition) to apply the semiconductor material onto substrates.

- Perovskite cells: Involve solution processing or vapor deposition to create lightweight and flexible PV layers.

- Multi-junction cells: Stack layers of materials to absorb different wavelengths of light, enhancing efficiency.

Would you like to dive deeper into any specific step or explore advanced methods like tandem solar cells?