Get Your Quote Wafer Quote FAST!

A a PhD student requested help with the following.

Question:

We are looking for a wafer which has basically good transparency and high temperature resistance(around 1400degC) and also needs to be thin(around 0.5mm). So far we knew that the possible candidates for that are sapphire, quartz wafer. Could you recommend any other possible candidate and the prices for those including sapphire and quartz wafer?

Answer:

Reference #104393 for specs and pricing.

| Crystal Material |

Dia |

Orientation |

Thickness |

Pol |

| Quartz Wafers |

4" |

42.75 °ST-Cut |

0.35mm |

DSP |

| Quartz Wafers |

4" |

36 °AT-Cut |

0.35mm |

DSP |

| Quartz Wafers |

3" |

42.75 °ST-Cut |

0.2mm |

DSP |

| Quartz Wafers |

3" |

36 °AT-Cut |

0.2mm |

DSP |

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

What Are The Available Quartz Wafer Applications?

Quartz wafers can be cut along various crystallographic orientations depending on their intended application. These orientations influence the physical, optical, and piezoelectric properties of the wafer. Below is a list of commonly used quartz wafer orientations:

1. Standard Cuts

2. Specialized Angled Cuts

-

AT-Cut

- Orientation: ~35°15' to the Z-axis in the X-Z plane.

- Features: Excellent frequency stability over temperature; widely used in quartz crystal oscillators.

-

BT-Cut

- Orientation: ~49° to the Z-axis in the X-Z plane.

- Features: Good temperature stability; used in resonators.

-

CT-Cut

- Orientation: ~+18° to the Z-axis in the X-Z plane.

- Features: Rarely used; specialized applications.

3. Rotated Cuts

-

ST-Cut

- Orientation: ~42°45' to the Z-axis in the X-Z plane.

- Features: Excellent temperature stability; commonly used in surface acoustic wave (SAW) devices.

-

SC-Cut

- Orientation: ~34° to the Z-axis in the X-Z plane.

- Features: Improved stability for high-precision oscillators; reduced sensitivity to mechanical stress.

4. Optical and Acoustic Applications

-

Optical Cuts

- These are typically Z-Cut or specially oriented to minimize birefringence or optimize transparency in certain wavelengths.

-

SAW Cuts

- ST-X-Cut: Used for SAW devices due to optimized acoustic properties.

5. Custom Angles

- Quartz wafers can be cut at custom angles (e.g., 20°, 30°, etc.) for specific piezoelectric or acoustic properties tailored to unique applications.

Choosing the Right Orientation

- Frequency Control Devices: AT-Cut, BT-Cut, SC-Cut.

- Surface Acoustic Wave (SAW) Devices: ST-Cut, ST-X-Cut.

- Optical Applications: Z-Cut.

- High-Temperature Applications: Specific cuts like SC-Cut for thermal stability.

If you are considering a specific application, I can help you determine the most suitable orientation!

Answer to Clients Quartz or Sapphire Question

Based on your specifications for a wafer with good transparency, high temperature resistance (around 1400°C), and thinness (around 0.5mm), here are some potential candidates and their properties:

1. Sapphire Wafers

- Properties:

- Excellent transparency in the UV to IR spectrum.

- High temperature resistance: melting point ~2050°C.

- Exceptional hardness and scratch resistance.

- Applications: Ideal for high-temperature optical and structural applications.

- Price Range: Typically, $100–$300 per wafer depending on size, quality, and surface finish.

2. Quartz Wafers

- Properties:

- High transparency across UV, visible, and IR spectra.

- High temperature resistance: softening point ~1670°C.

- Good chemical stability and low thermal expansion.

- Applications: Widely used in high-temperature optics and electronics.

- Price Range: Around $50–$150 per wafer depending on size, orientation, and surface specifications.

3. Additional Candidates

Here are a few other materials that may meet your needs:

Recommendation:

If optical transparency in the visible spectrum is crucial, sapphire or quartz remain your best options. For ultra-high-temperature applications or unique spectral needs, you might consider SiC or AlN depending on the specific wavelength and environmental constraints.

Next Steps:

Please let us know:

- The preferred size and surface finish of the wafers.

- The quantity you’re looking to procure.

- Any additional requirements (e.g., single-side polished, double-side polished).

Based on this, I can provide a detailed quote for sapphire, quartz, and alternative wafers.

Let me know if you’d like further assistance refining this response or sourcing a price quote for these wafers!

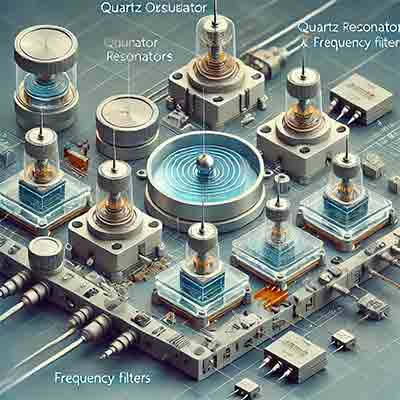

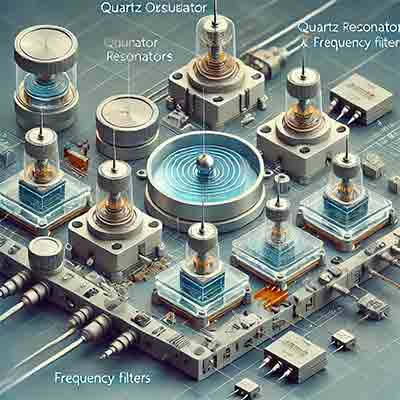

What Applications Use Quartz Wafers?

Quartz wafers are highly versatile and find use in various applications across multiple industries due to their unique physical, chemical, and optical properties. Here are some common applications:

1. Optical and Photonic Devices

- UV and IR Windows: Quartz's transparency to a broad spectrum of light, including ultraviolet (UV) and infrared (IR), makes it ideal for optical windows and lenses.

- Photolithography: Quartz wafers are used as substrates for photomasks in semiconductor manufacturing due to their low thermal expansion and high optical clarity.

- Waveguides: Quartz wafers are used in optical waveguide fabrication for telecommunication and data transfer.

2. Microelectronics

- Piezoelectric Devices: Quartz wafers are used in oscillators, resonators, and frequency filters due to

their stable piezoelectric properties.

their stable piezoelectric properties.

- SOI Substrates: Quartz is used as an insulating layer in Silicon-on-Insulator (SOI) technology for advanced semiconductor devices.

3. Biosensors and Lab-on-a-Chip

- Microfluidics: Quartz wafers are employed in microfluidic devices and lab-on-a-chip systems for their chemical inertness and biocompatibility.

- Biosensors: Quartz's transparency and inertness make it suitable for optical and electrochemical biosensors.

4. High-Temperature Applications

- Crucibles and Substrates: Quartz wafers are used as substrates or containers in high-temperature processes like epitaxial growth or thermal oxidation due to their thermal stability.

5. Advanced MEMS and NEMS

- Micro and Nano-Electromechanical Systems: Quartz wafers serve as substrates for MEMS and NEMS devices where high precision and thermal stability are critical.

6. Scientific Research

- Thin Film Deposition: Quartz is often used as a substrate for thin-film deposition and analysis due to its smooth surface and chemical resistance.

- Spectroscopy: Quartz wafers are employed in spectroscopy for their transparency and low fluorescence interference.

7. Specialized Applications

- Quantum Computing: Quartz wafers are investigated for use in quantum computing substrates.

- Aerospace and Defense: Quartz's high radiation resistance and thermal stability make it suitable for aerospace and defense applications.

If you're considering quartz wafers for a specific application, let me know—I can help narrow down the specifications or provide additional details.

Are There Any Quasi-Crystalline Quartz Wafer Available?

Quasi-crystalline quartz wafers are not a standard product in the industry because quartz in its natural or synthetic form typically exhibits a crystalline structure (e.g., α-quartz or β-quartz) or an amorphous structure (fused silica). Quasi-crystalline materials, which are neither purely crystalline nor amorphous, represent a distinct class of materials with unique structural properties but are not commonly associated with quartz.

Key Points:

-

Quasi-Crystals and Quartz:

- Quasi-crystals have an ordered structure but lack periodicity, unlike conventional crystals.

- Quartz does not naturally form quasi-crystalline structures. Instead, it is a well-ordered crystalline material in its common forms or fully amorphous when fused.

-

Alternative Materials:

- If you need materials with quasi-crystalline properties, metallic alloys (e.g., Al-Mn or Al-Cu-Fe) are common examples, but they differ significantly from quartz in composition and application.

-

Applications Requiring Unique Structures:

- For specific applications that may benefit from quasi-crystalline-like properties (e.g., unique optical or thermal behavior), engineered metamaterials or photonic crystals might be more appropriate.

-

Custom Fabrication:

- If you are investigating a novel application or need a material resembling quasi-crystalline quartz, it may involve custom fabrication using advanced materials science techniques like controlled doping, engineered defects, or artificial structuring.

Let me know if you need help exploring alternatives or designing a custom solution for your application.

What are the uses of a high purity quartz wafer boat?

A high-purity quartz wafer boat is a critical component in semiconductor fabrication and other high-tech industries. Its main uses include:

1. Wafer Processing

- Thermal Processing: Quartz wafer boats are used to hold silicon wafers during thermal processes such as oxidation, annealing, and diffusion. Quartz is ideal due to its thermal stability, low thermal expansion, and resistance to high temperatures.

- Chemical Vapor Deposition (CVD): These boats support wafers during thin-film deposition processes.

- Etching Processes: In processes that involve etching materials from the wafer, quartz's chemical inertness prevents contamination.

2. Cleanroom Compatibility

- High-purity quartz is non-reactive and resists contamination, making it suitable for cleanroom environments where wafer purity is paramount.

3. Optoelectronics

- Quartz boats are used for handling substrates in the production of optoelectronic devices, such as LEDs and photonics components, where high temperatures and purity are essential.

4. Research and Development

- Quartz boats are employed in experimental setups requiring high-temperature stability and chemical inertness, such as studies on material properties or novel fabrication techniques.

5. Solar Cell Manufacturing

- They are used to hold silicon wafers during processes like doping and annealing in the production of photovoltaic cells.

6. Precision Applications

- The high purity of quartz minimizes contamination, which is critical for fabricating advanced semiconductor devices and MEMS (microelectromechanical systems).

Advantages of Quartz Wafer Boats:

- High Thermal Stability: Withstand extreme temperatures without deformation.

- Chemical Resistance: Inert to most chemicals, preventing reactions during processing.

- Low Contamination Risk: Ultra-pure material ensures wafers remain uncontaminated.

- Durability: Can withstand repeated thermal cycling.

Would you like guidance on selecting or maintaining quartz wafer boats for specific applications?

their stable piezoelectric properties.

their stable piezoelectric properties.